Custom Mirrors

Knight Optical can provide custom optical mirrors for use as reflectors across different wavebands dependent on the coating that is applied. Our coatings include, but are not limited to, the following:

Knight Optical can provide custom optical mirrors for use as reflectors across different wavebands dependent on the coating that is applied. Our coatings include, but are not limited to, the following:

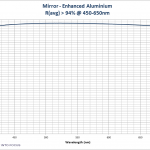

- Enhanced aluminium coating, 94% reflectivity for use in visible applications.

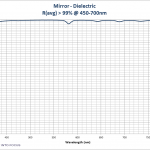

- 99.9% dielectric coating for laser use in visible applications.

- UV aluminium/MgF2 coating for use in UV applications down to 180nm.

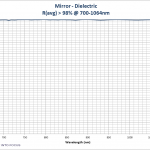

- 98.5% NIR dielectric coating for laser use in the near infra-red region.

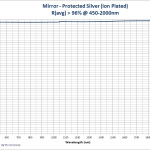

- Ion plated protected silver coating for use in NIR to 2000nm.

- Protected gold coating for use from 750nm to far infra-red applications.

Mirror coatings can be applied to a different optical components including window, prisms and concave lenses. We can offer a multitude of substrates dependent on the application, however glass with low thermal expansion is most commonly used including float glass and borosilicate.

Below are a few examples of the coatings we can apply to an optical surface:

Contact our technical sales team with your enquiry.

Browse the categories below for further information on typical mirror types that Knight Optical can help with:

Additional Information

- For a fast turnaround on small orders, it is possible to edge down our stock mirrors to meet more specific requirements.

- Aluminium can be used as the mirror substrate for more LWIR and laser applications.

Quality Assurance

- Reflection scans are conducted on our Agilent Cary 7000 Spectrophotometer which can perform spectral scans at multiple angles of incidence which can be critical in mirror applications. Typically, mirror performance is given at 0° or 45° and Knight Optical can provide ASCII data and graphs with the scan results.

- The flatness and irregularity of our optical mirrors are tested on our Zygo Verifire XPZ interferometer, this value can be given at a chosen design wavelength.

- We check the parallelism on our Trioptics PrismMaster which is accurate to 3 arc seconds.

- We can also test infrared optical components on our Agilent Cary 660 FTIR spectrometer.

- All optics are 100% visually inspected before packaging, our staff are trained to ISO 10110 and MIL-0-13830A, and can check down to 10/5 scratch/dig which is especially critical in laser applications.

Our Catalogue

Inside Knight Optical’s catalogue you’ll find details of the industries we serve as well as the many other services we can offer. It also showcases hundreds of our most popular products, supported by useful technical information, to help you choose the right part for your application.

Click below to view our digital catalogue now.